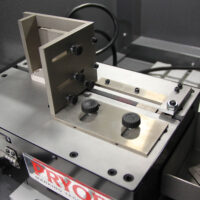

Bench Laser

The Bench Laser from Pryor stands out as our premier benchtop laser marking machine, versatile across various industries, catering to numerous marking and traceability needs

Our latest iteration of this machine surpasses its predecessor, boasting several pivotal enhancements and technological advancements, positioning it as one of the most proficient benchtop laser marking and engraving machines in today’s market.

Equipped with our cutting-edge Traceability Software, this machine ensures seamless integration and efficient operation. Additionally, users have the option to enhance their experience further by incorporating a touchscreen controller, simplifying laser operation and facilitating intuitive layout creation.

- Fully automatic vertical door is standard across the bench-top range

- Larger internal area for marking larger parts

- Automatic Z-axis control

- ‘Pilot’ beam for ease of mark placement

- Class 1 laser, Made in Britain, manufactured in the UK at our Headquarters in Sheffield

The Bench Laser from Pryor is our bench top laser marking machine that can be used across different industries for many common marking, engraving, etching and traceability applications, including laser engraving.

- Features

- Specification comparison

- Accessories

Features

Bench Laser Technical Details

- 2.5m or 3m Fibre optic in protective conduit with 8mm collimator/isolator

- Average diode life exceeds 50,000 hours

- Basic Frequency: 30 to 60 KHz

- Standard frequency: 20 to 200 KHz

- Pro frequency: 1,6 to 1000 KHz with adjustable pulse durations for a wider range of material and marking style capabilities.

Bench Laser Dimensions

- Height: 760mm (1160mm with door open)

- Width: 710mm

- Depth: 750mm

Lens Marking Area

- FT100 – 60 x 60mm

- FT150 – 100 x 100mm

- FT254 – 150 x 150mm

Specification comparison

| 20W Economy | 20W Standard | 20W Pro | |

| Pulse Energy | 0.7mJ | 1mJ | 1mJ |

| Average Power | ~18.5W | 20W | 20W |

| Beam Quality M2 | 1.3 | 1.6 | 1.6 |

| Polarization | Random | Random | Random |

| Power Adjustment | 5 – 100% | ||

| Pulse Duration @ 20KHz | ~85ns | 100ns | 1.5, 2.5, 4, 8, 16, 30, 50, 120, 200, 350 |

| Repetition Rate | 30 KHz to 60KHz | 20 KHz to 200 KHz | 1.6 KHz to 1000 KHz |

| Long Term Power Stability | 5% | ||

| Operating Temperature | 0 to 42°C | ||

| Cooling | Active Air Cooling | ||

| Fibre Optic | 2.5m | 3m | 3m |

| Power | Less Than 200W – 110 or 220 VAC | ||

| Product Warranty | 1 year | 2 years | |