Laser Engraving on Metal: A Durable Investment

Laser engraving has emerged as a leading technology for permanently marking metal. Unlike traditional methods like ink or labels that can fade or peel away, laser engraving metal creates a lasting impression directly on the material itself. This makes it ideal for a wide range of applications, from industrial manufacturing to personalized gifts.

But how does it work?

Laser engraving utilises a highly focused laser beam to precisely remove material from the metal surface or alter the material itself to create a contrast on the surface. This process creates a permanent mark that is both highly visible and incredibly durable. The precision of the laser allows for intricate designs, text, and also 1D and 2D codes to be etched onto the metal with exceptional accuracy and consistency.

In this blog post, we’ll explore the various facets of laser engraving on metal, including:

- The science behind the technology

- The advantages of laser engraving

- Common applications

- Choosing the right laser engraver

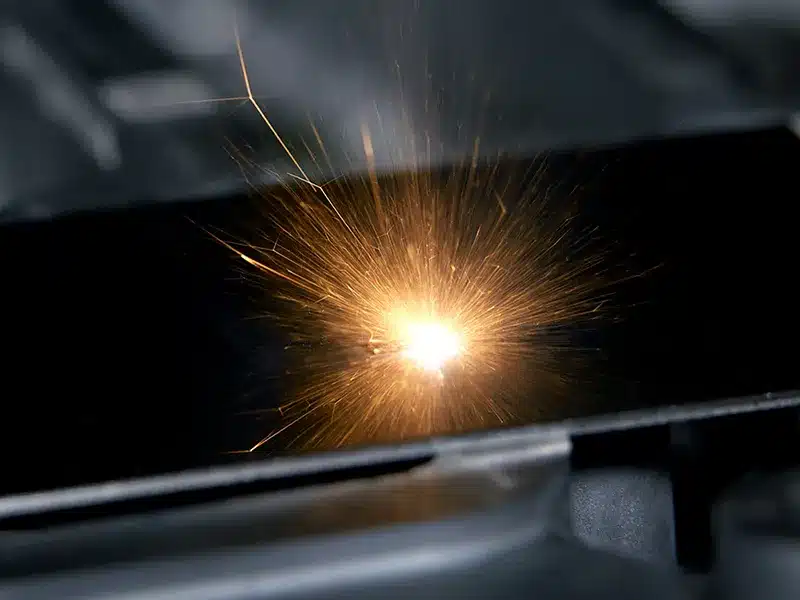

Laser engraving relies on the principle of the laser interacting with the surface of the metal and transferring energy in the form of heat. Different types of lasers are used depending on the material being engraved. Fiber lasers are commonly employed for metal marking due to their ability to generate a high-intensity beam that is readily absorbed by the metal. The laser beam heats the metal surface rapidly causing a ‘burnt’ appearance on the surface. If wanting to create a mark with depth, the laser will remove material, and this is seen as sparks when viewing the marking process This precise nature of laser marking is a combination of the incredibly small spot size of the laser beam and the precision control of the mirrors that are used to direct the laser beam onto the surface of the material. The depth and appearance of the engraving can be controlled by adjusting the laser’s power, speed, and frequency.

Compared to other marking techniques, laser engraving offers numerous advantages. Firstly, it produces marks with exceptional precision and detail, making it suitable for intricate designs and small text. Secondly, laser engraving is a non-contact process, eliminating the need for physical contact with the metal surface, and reducing the risk of damage or contamination. This also implies to fixturing and tooling when comparing it to other marking technologies like dot peen marking. Finally, laser engraved marks are highly resistant to wear and tear, ensuring their longevity even in harsh environments. This makes them ideal for applications requiring permanent identification or traceability through a long life cycle.

Laser engraving finds applications in a diverse range of industries. In manufacturing, it’s used for marking parts with serial numbers, barcodes, and logos for traceability and branding purposes. In the medical field, it’s used for engraving surgical instruments and implants with critical information. The jewellery industry uses laser engraving for personalization, allowing for intricate designs and custom messages to be added to rings, pendants, and other items. Even in the realm of electronics, laser engraving plays a crucial role in marking components and circuit boards.

Selecting the appropriate laser depends on several factors, including the type of metal being engraved, the desired level of detail, and the volume of work. There are then many practical considerations that would influence the type of system most suited to any given application:

- Volume of parts

- Variation of parts

- Cycle time requirements

- The size of parts

- Integration with other manufacturing processes

- Software integration requirements.

Why laser engraving is an ideal choice for marking metals:

- Durability: Laser-engraved metals are naturally resistant to wear and tear, making them a great option for items that will be handled frequently or exposed to harsh conditions. Laser engraved marks on metal are usually permanent.

- Versatility: Laser engraving can be used on a wide range of metals, from soft metals like aluminium to harder metals like stainless steel.

- Customisation: Laser engraving allows for intricate designs and personalised messages to be etched into the metal surface.

Why choose Pryor?

Pryor offers high-quality fibre laser engraving machines, ideal for metal engraving. Our machines are known for their precision, durability, and versatility. They can handle a wide range of metals and produce intricate designs with speed and efficiency. Pryor machines are easy to operate and come with excellent customer support, making them a reliable choice for businesses seeking top-notch metal marking solutions. Our Traceability software is developed in-house and designed to work with our marking machines. It offers customisation and can easily integrate with a customers’ network for databasing and data input.

In addition to the laser solutions that Pryor offers as standard machines, we also offer a ‘design to order’ service where our in-house mechanical and software designers create a bespoke solution to fit our customer’s individual requirements

Conclusion:

Laser engraving on metal is a durable and customisable option for creating lasting impressions. By choosing the right metal and taking proper care of your engraved items, you can benefit from your laser engraving for many years to come.