Why Choose Laser or Dot Peen Marking for your Production line marking?

Modern manufacturing demands solutions that are as efficient as they are effective. Laser and dot peen marking machines offer a range of benefits that go beyond simple identification:

- Works on Multiple Materials – Metals, plastics, composites—you name it. Our machines can handle them all, making them a versatile choice for diverse industries.

- Built to Last – Unlike stickers or ink-based methods, laser and dot peen markings resist abrasion, corrosion, and harsh environmental conditions.

- Fast and Efficient – High-speed marking means less downtime and a significant boost in productivity.

- Unrivalled Precision – Whether it’s intricate logos or tiny serial numbers, these machines deliver crisp, legible results every time.

- Seamless Integration – Designed to fit right into your existing production setup, reducing disruptions and increasing workflow efficiency.

Contact Us

If you need some help or some advice about integrating Marking or Traceability into your production line. call us today on +44 (0) 114 276 6044 or fill in the form below and speak to our team.

The Shift from Labels to Direct Marking

Still relying on labels? You might want to reconsider. While they’ve been a go-to solution for years, labels come with a host of drawbacks—fading, peeling, detaching, and even counterfeiting. Direct marking solves these issues at the source:

- Long-Term Durability – No more worn-out or unreadable labels. Direct markings last as long as the product itself.

- Permanent and Tamper-Resistant – Unlike stickers that can be removed or damaged, direct markings are a secure and lasting solution.

- Streamlined Data Integration – Direct markings can be linked with digital tracking systems, making inventory management a breeze.

- Faster, More Efficient Process – Skip the hassle of applying and replacing labels—direct marking is quicker and requires less maintenance.

- Enhanced Security – Reduces the risk of product counterfeiting and ensures authenticity in high-value industries.

How Can You Use Production Line Marking?

The applications for laser and dot peen marking stretch across multiple industries. Whether you’re in aerospace, automotive, electronics, or medical manufacturing, these machines are up to the task. Here’s how they can be used:

- Serial Numbers – Essential for traceability, unique serial numbers allow for precise tracking and identification.

- Barcodes – A critical part of supply chain management, ensuring smooth logistics and inventory tracking.

- Logos and Branding – Reinforce your company’s identity with crisp, professional product markings.

- Date and Lot Codes – Essential for regulatory compliance and tracking production history.

- Industry-Specific Compliance – Meet stringent industry requirements with high-precision, permanent markings.

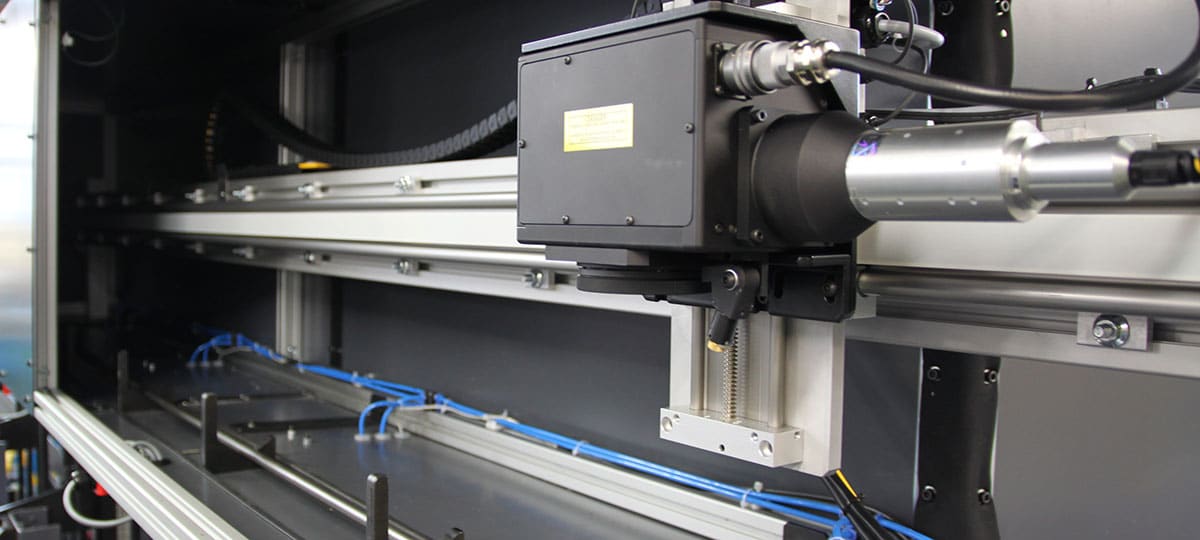

Automation and Robotics: The Future of Marking

Manufacturing is evolving, and automation is leading the way. Our marking machines aren’t just standalone units—they integrate seamlessly into fully automated production lines. When paired with robotics, the benefits speak for themselves:

- Increased Output – Automated systems cut down manual labour, speeding up production without sacrificing quality.

- Higher Accuracy – Remove the risk of human error and ensure every marking is consistently flawless.

- Adaptable and Scalable – Whether your production needs change or expand, these machines adjust to fit your workflow.

- Smooth Integration – Works in harmony with existing automation setups, making for a fully synchronised operation.

Need Something Custom? We’ve Got You Covered

No two production lines are identical, which is why off-the-shelf solutions aren’t always the best fit. If your marking requirements are unique, we can design and build a custom machine that integrates seamlessly into your operations.

Why Go Custom?

- Tailored to Your Needs – Get a solution designed specifically for your materials, marking style, and production volume.

- Optimised Efficiency – A machine built for your workflow means fewer delays and better overall performance.

- Adaptable to Change – Custom solutions can evolve with your business, keeping pace with future growth.

- Seamless System Integration – Designed to slot into your existing setup without unnecessary modifications or disruptions.

Ready to Enhance Your Production Line?

If you’re looking to improve efficiency, ensure product traceability, and achieve long-lasting, high-quality markings, we can help. Get in touch today to explore how laser and dot peen marking machines can revolutionise your production process. Let’s make manufacturing easier, faster, and more reliable—one mark at a time.