In the aerospace & aviation industry, where safety and reliability are paramount, ensuring complete traceability of every part is non-negotiable. At Pryor, we understand the critical role marking and traceability machines play in maintaining the integrity of your aircraft.

Our industry-leading marking and traceability solutions empower you to:

- Meet Rigorous Standards: Comply with stringent aerospace regulations and quality control demands. Our machines seamlessly integrate with existing processes, ensuring clear, permanent, and tamper-proof marking on even the most delicate components. Standards include (But not limited to): AS9132, JES131, AIM-DPM-Guideline, MIL-STD-130, RRES90005, RRES90003, PWA309, PWA310, P23TF3, P23TF10, AS478, ISO15434 and ISO16022.

- Maximize Safety: Rapidly identify and replace faulty parts with precise traceability and integrated Vision camera systems. This minimizes downtime, reduces costs associated with recalls, and most importantly, enhances passenger safety.

- Streamline Operations: Boost efficiency and productivity with automated marking solutions. Our intuitive systems integrate seamlessly with your production lines, eliminating manual processes and human error.

- Unmatched Versatility: We offer a wide range of marking technologies, including:

- Laser Marking: Aerospace laser part marking is ideal for permanent, high-resolution marking on various materials like metals, composites, and plastics.

- Dot Peen Marking: Creates precise and durable marks on critical components without compromising material integrity.

- Seamless Integration: Our marking and traceability systems and traceability software integrate effortlessly with existing data management software, allowing for real-time part tracking throughout the entire lifecycle – from manufacturing to maintenance.

Benefits of Choosing Pryor:

- Experience You Can Trust: We have a proven track record of providing reliable and robust marking solutions to world leading aerospace manufacturers worldwide.

- Unwavering Support: Our dedicated team of engineers and technicians are committed to providing exceptional customer service and ongoing support.

- Future-Proof Technology: We invest heavily in research and development to ensure our machines stay ahead of the curve, meeting the evolving needs of the aerospace industry.

- Not one size fits all: Pryor Solutions offers full customizability and the ability tocrate tailor made solutions that are designed to your exact needs

Contact us today

Get in touch for a free consultation and discover how our marking and traceability solutions can elevate your aerospace manufacturing processes.

Dot Peen Marking: A Critical Advantage for Aerospace

The aerospace industry demands the utmost precision and reliability. From critical components to intricate assemblies, permanent and unambiguous identification is paramount. Dot peen marking technology delivers a significant advantage by:

- Withstanding Extreme Conditions: Aerospace components face harsh environments, including extreme temperatures, corrosive chemicals, and high pressures. Dot peen markings remain legible even under these demanding conditions, ensuring long-term traceability.

- Marking Diverse Materials: The aerospace industry utilizes a wide array of materials, from lightweight alloys to high-strength composites. Dot peen marking effectively marks all these materials, providing consistent and reliable identification across the manufacturing process.

- Ensuring Data Integrity: Accurate and legible markings are crucial for regulatory compliance and safety. Dot peen marking systems can incorporate high-resolution fonts and barcodes, ensuring data integrity and facilitating efficient data capture throughout the supply chain.

- Improving Production Efficiency: Automated or High-speed dot peen marking systems can significantly increase production throughput, reducing downtime and improving overall manufacturing efficiency.

By addressing the unique challenges of the aerospace industry, dot peen marking technology plays a critical role in enhancing quality, improving safety, and streamlining operations. Find out more about our Dot Peen Marking Machines

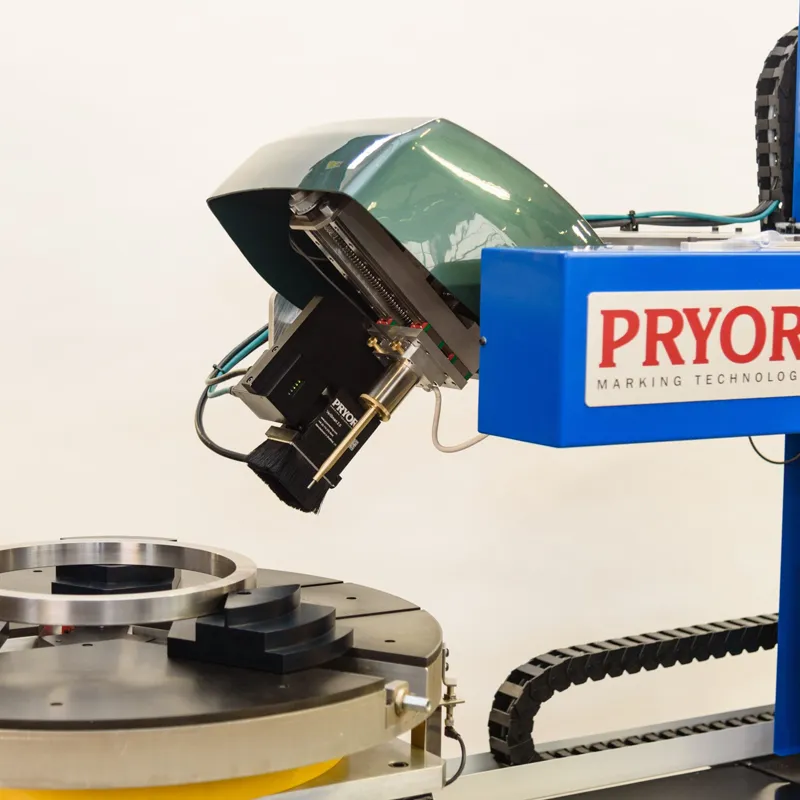

Multi-axis Marking Machine for Aerospace

The pioneering Multi-axis Marking Station is a marking and verification machine. This dot-peen marking and machine vision system is designed to mark and verify large, cylindrical components such as aerospace turbine housings.

The dot peen marking head has a number of different marking window size options depending on your requirements. The marking head has x- and y-axes that move the stylus within the marking window and is mounted on a z-axis column that can either be manually adjusted or motorised. The z-axis column positions the marking head at the optimal distance from the component to be marked. The state-of-the-art ‘autosense’ feature automatically positions the stylus at the optimal distance from the component at the beginning of each marking operation, ensuring repeatability and consistency of the mark.

The marking head also houses a machine vision camera with an integrated light source. The camera is provided with a shroud to control the lighting conditions and minimise the effects of any variations in ambient lighting. This machine vision has the ability to verify the quality of the marked codes against international marking standards, including: AS9132, JES131, AIM-DPM-Guideline, MIL-STD-130, RRES90005, RRES90003, PWA309, PWA310, P23TF3, P23TF10, AS478, ISO15434 and ISO16022. It also allows the operator to read and capture data from the marked component; critical for data-driven manufacturing and process control, allowing measurability and eliminating quality defects. The machine vision camera also enables the pioneering automated component alignment capability. This determines the correct position of the mark on the component, automatically rotating the component to the correct location using a “learnt” reference feature.

The component is rotated on a motor driven rotating table which forms the basis of the fixture and allows controlled rotation of heavy parts. The rotating table is available in various dimensions to fit the part being marked. The marking head is mounted on a programmable motorised horizontal axis which alters the proximity of the part to the marking head. It also allows for very large parts to be marked by the machine.

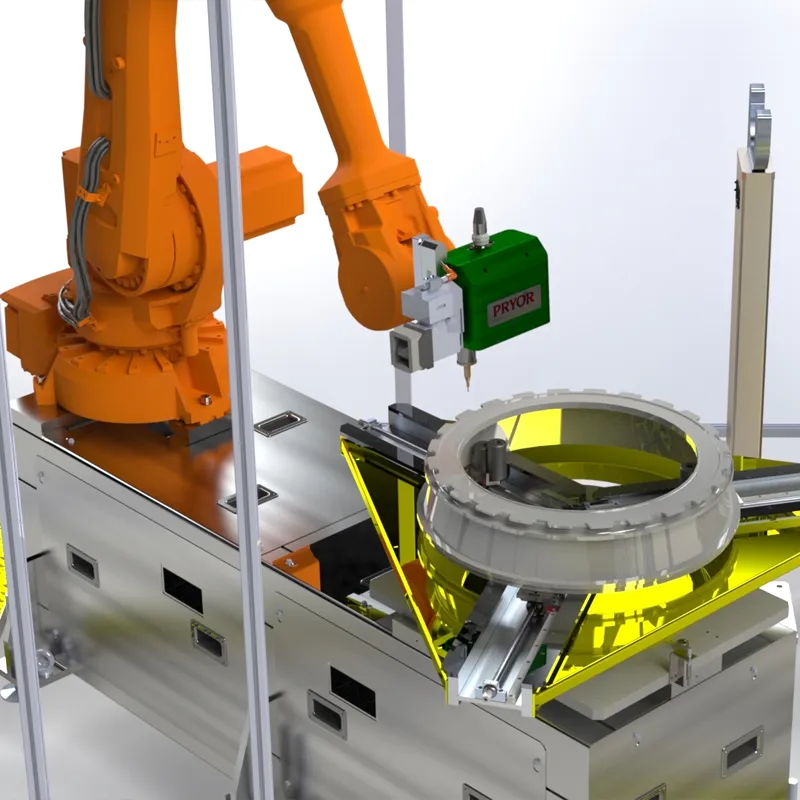

Robotic Marking Machine for Aerospace

Introducing a robot into a marking and verification solutions provides the ultimate flexibility and automation. Our Robotic Marking and Verification Station uses the robot in conjunction with a customisable rotating table to enable a mark to be applied on almost any surface.

The dot peen marking head is mounted directly to the robot and the X-Y movement is used to apply the mark, once the marking head has been correctly positioned.

Controlling and positioning the robot for the marking cycle can done with a standard marking layout in our traceability software but we also have the option to introduce a ‘feature find and offset’ function to ensure absolute accuracy with regard to positioning the mark.

The integrated vision system also provides read, validation, and verification of the applied mark to make sure that you are adhering to the relevant specifications

Latest Aerospace and Aviation Related Posts

Pryor to Exhibit at Paris Air Show 2025

We’re thrilled to announce that Pryor will be exhibiting at the Paris Air Show 2025, the world’s most prestigious aerospace event, taking place from 16th to 22nd June at the iconic Parc des Expositions de Paris-Le Bourget. You’ll find us in Hall 4 – Stand BC168, where we’ll be showcasing our...

Key Tools for Traceability Marking

Laser engravers and Dot Peen markers are powerful tools for implementing effective traceability in manufacturing. These technologies allow for the precise and permanent marking of products with unique identifiers, such as serial numbers, barcodes, or QR codes. Both methods are versatile and can be used to mark a...

1D vs. 2D Barcodes: A Quick Guide

In today's data-driven world, barcodes have become an integral part of our daily lives. From scanning groceries at the supermarket to boarding a plane, barcodes streamline various processes and provide traceability for businesses. But have you ever wondered about the difference between 1D and 2D barcodes? Let's dive into the...

Label Laser Marking Systems for Modern Automotive Traceability

Introduction: Pryor have become a trusted leader in delivering complex and reliable marking systems within the automotive industry. These have ranged from Robotic and Manipulator based VIN Marking Systems for OEMs, to integrated high speed marking systems for the Automotive supply chain. More recently, we have developed and delivered a number...

What is SPEC 2000?

In 1936 the ATA (Air Transport Association) was formed to represent the aerospace industry. The ATA Spec 2000 is an international standard that was subsequently developed to improve communication and information flow between members of the interconnected global supply chain network. Now renamed as Airlines for America, the ATA continues...

What is IAQG Part Marking?

The IAQG is the International Aerospace Quality Group, a body formed by the Society of Automotive Engineers (SAE). It brings together OEMs and suppliers from across the Aerospace Industry to agree international quality standards. The IAQG website can be visited here: www.sae.org/iaqg/ The IAQG provides standards regarding many topics, one...

What is the AS9132 Specification?

AS9132 is a specification for the Direct Part Marking of aerospace components. It is issued by the International Aerospace Quality Group (IAQG) to define the process requirements for 2D Data Matrix part marking, relative to metallic parts. The standard provides process help for the manufacturer to produce and maintain the optimum...

A Guide To Aerospace Part Marking Standards

Part marking standards are very common in the aerospace manufacturing sector, due to the amount of complexity and detail that goes into producing their components. As a supplier of components to aerospace organisations, you must abide by these marking standards to ensure the smooth application of the components you...

What is the RRES 90003 Specification?

RRES 90003 is a global engineering specification for Identification Marking Methods and Controls. It is a Rolls-Royce global document that was compiled for new component designs and will be called out in place of the previous system of JES and EDI specifications. RRES 90003 defines and controls identification marking methods and other...